· Ioana Cozmuta, Nicole Wagner, Remus Osan, Brian Motil · Papers · 1 min read

Machine Learning Optimized Process Control and Yield of Artificial Retina In-Space Manufacturing

LambdaVision is developing an artificial retina (AR) to restore vision for millions of people suffering from retinal degenerative diseases

Abstract

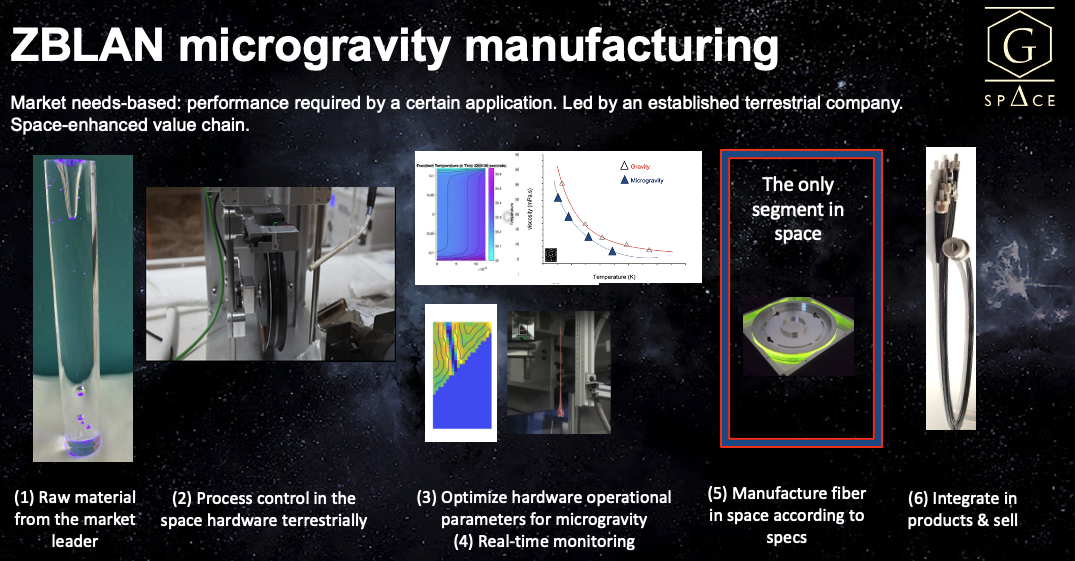

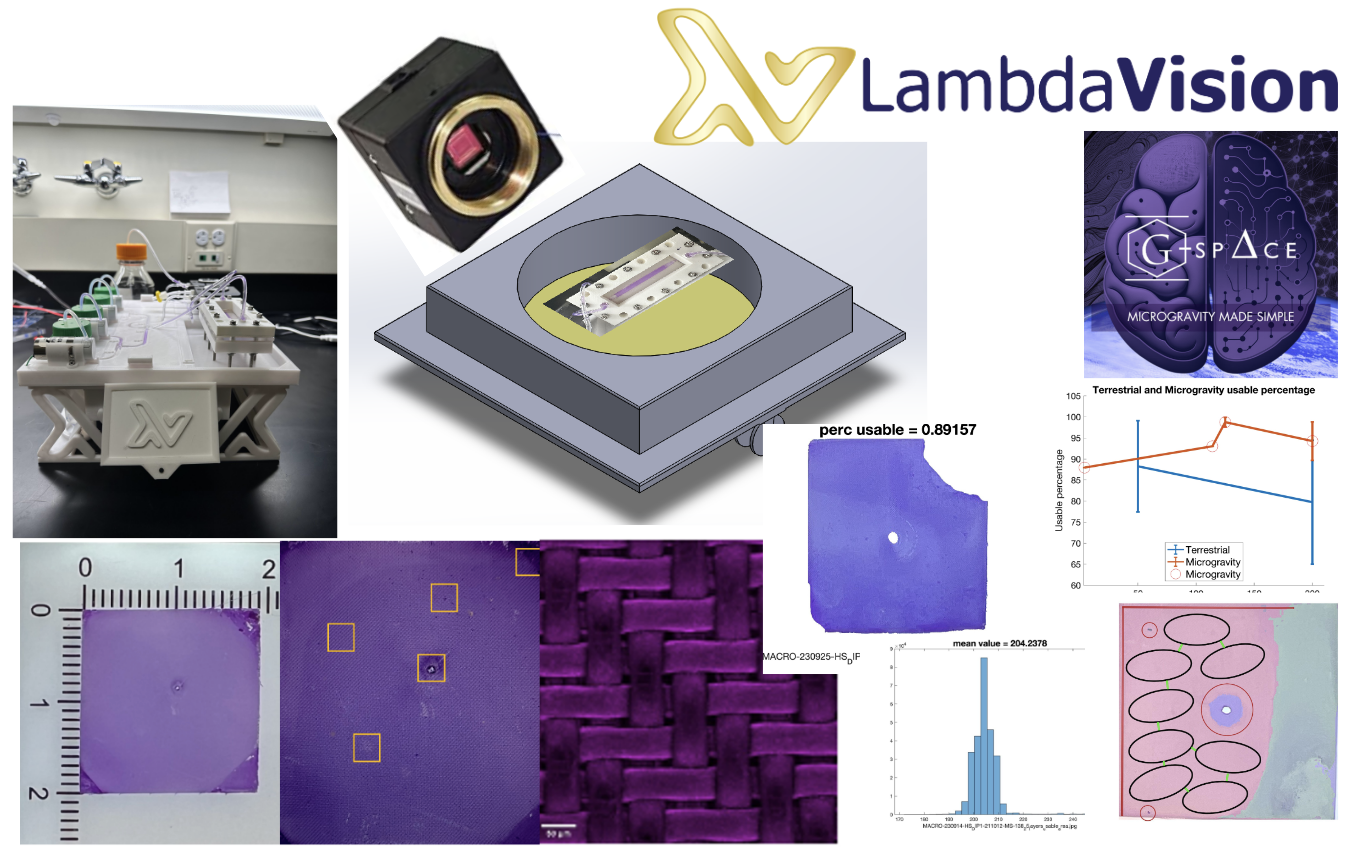

LambdaVision is developing an artificial retina (AR) to restore vision for millions of people suffering from retinal degenerative diseases. These ARs are manufactured using a layer-by-layer (LBL) technique, which is sensitive to gravitational effects.

Nine missions to the ISS have demonstrated LambdaVision’s manufacturing hardware and have shown proof of concept to produce thin films in Low Earth Orbit (LEO). Reliability of the manufacturing process and compliance with the Food and Drug Administration (FDA) is necessary for safety, efficacy, and implant quality.

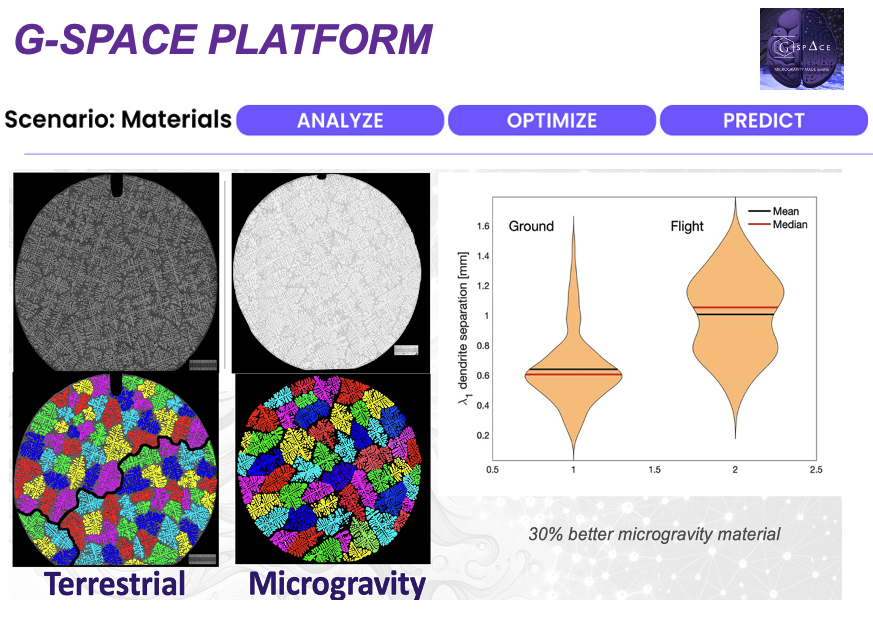

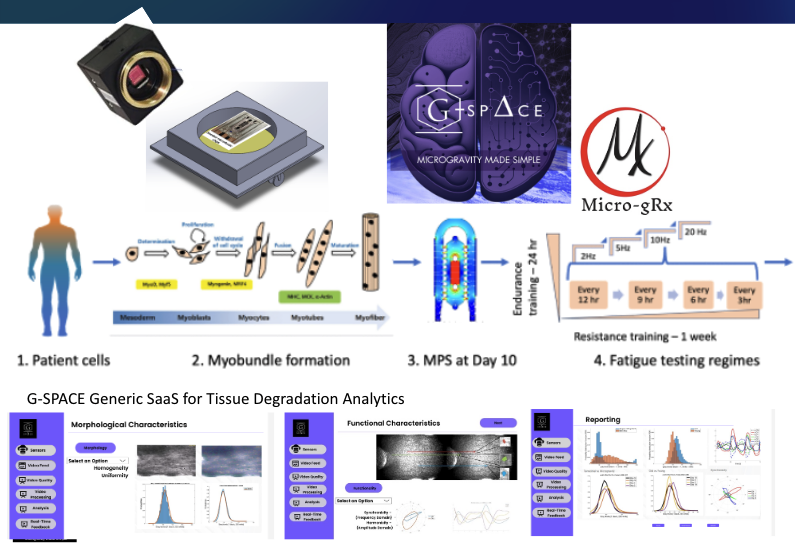

LambdaVision has partnered with G-SPACE to develop an artificial intelligence/machine learning (AI/ML) system to better characterize the AR manufacturing process. This system provides rapid-response analytics, monitoring, and optimization of the manufacturing process to improve AR production, reduce costs, and accelerate commercialization.

Integration of real-time process controls into the manufacturing method will enable higher levels of accuracy and operational efficiency by refining production workflow and will provide the framework for future technologies looking to manufacturing in space.